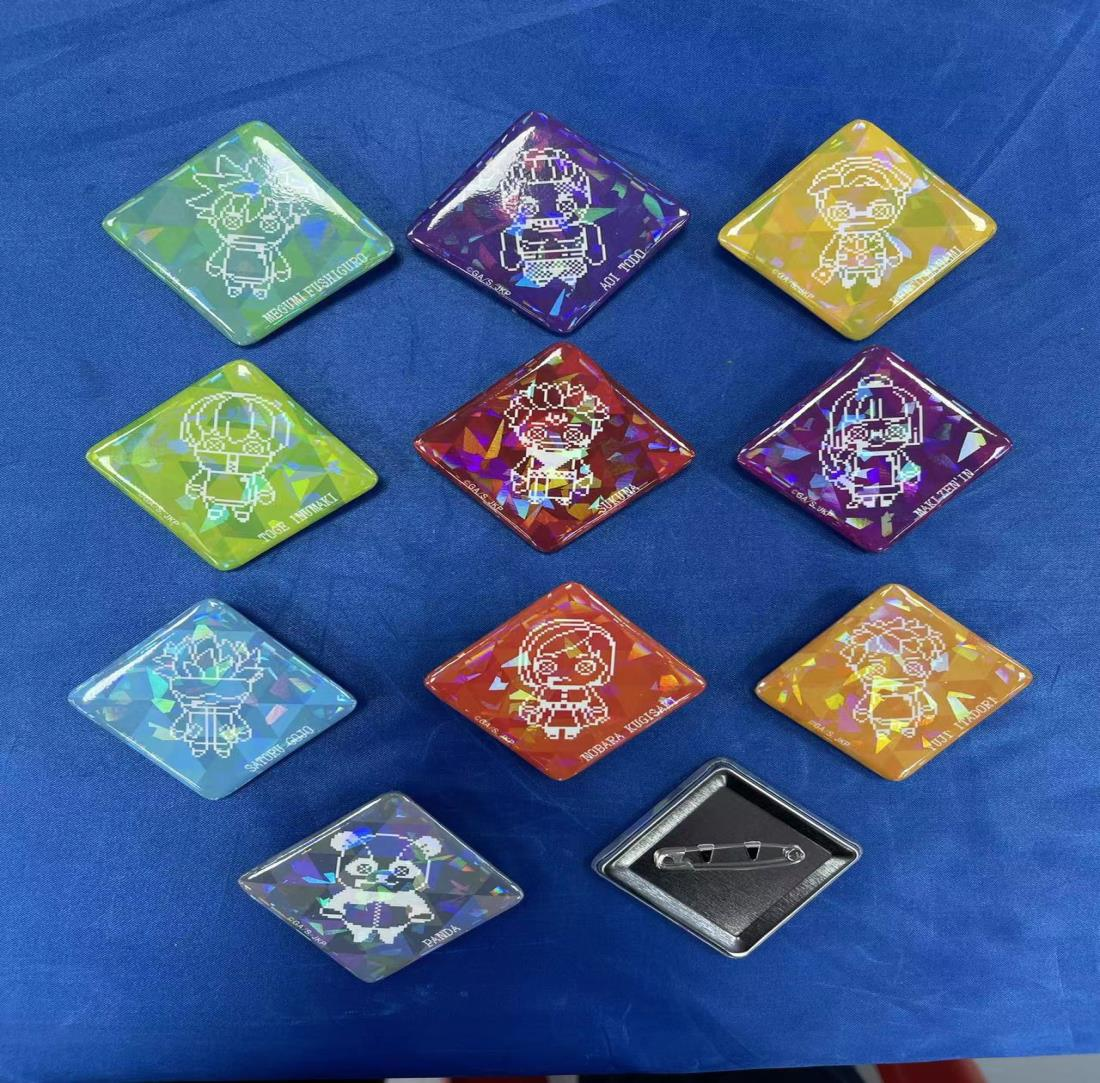

Tinplate badge-Buton badge-Badge pin

Workflow

| Product Name | Tinplate badge |

| Material | Tin |

| Reference price |

0.5~5USD |

| Make less orders | 500PCS |

| Delivery date | 5 days delivery |

| OEM | OK |

| Place of production | made in China |

| Other | Including packaging |

Tinplate is iron and not just iron, but a tin sheet with a layer of tin on the surface. Because there is a layer of metal tin on the surface of the iron sheet, it is not easy to rust. It is also known as tinplate, which is also known as tinplate. Since the tinplate used to manufacture cans was imported from Macao at that time, the English name of Macao can be read as tinplate, so it is called tinplate. The name of tinplate comes from this and has been used until now.

The tinplate badge originally originated in Europe and the United States, but it has become popular in China in recent years. Because the price of tinplate is relatively low and the product shape is beautiful, it is deeply loved by the majority of consumers and friends in the market. The production cost of tinplate is lower than that of iron, copper, aluminum, zinc, alloy, etc., but the appearance color of the product is superior to that of other materials.

The surface of the tinplate badge can be made into any pattern. As long as you have a design draft or material, we can help you design the pattern you want. As long as you can design it, there is no color that cannot be printed. Most badges made of other materials can only be made in a single color. If there are too many colors, they can't be produced.

With the continuous recognition of the tinplate badge, the application of the badge is also becoming wider and wider, from the smile badge worn by the salesmen in major shopping malls, the school badge, the class badge, the wedding corsage, the customized LOGO badge for enterprises, and so on. Because of the quality and low price of the tinplate material, the tinplate badge is also often used as promotional gifts for advertising. With the innovation of production types, from the previous single tinplate badge to the current tinplate key chain, tinplate refrigerator stickers and other forms of handicrafts.

The overall manufacturing process of the tinplate badge is not very complicated. The following is a brief introduction to Boxin Can Factory:

Step 1: First, make a good film and put the paper into the printer for printing. Of course, this paper is not the common type of writing paper, but a kind of paper called coated paper. Everyone should have some contact in daily life, like many paper business cards are coated paper.

Step 2: Take the paper printed in the first step to the peritoneum. The peritoneum has two kinds of glossiness: bright and matt. The matt surface looks a little rough, like the surface of ground glass, without glare and glare, giving the user a sense of stability and elegance. If bright, the surface is very smooth, with strong mirror reflection effect and glare. Give users a bright and gorgeous feeling. Of course, the specific peritoneal effect is completely determined according to the needs of customers' products.

Step 3: use the indentation machine to press the shape, which is to press the desired shape through the machine, which is equivalent to using the machine to cut the corresponding pattern on a large piece of pattern, cutting out the desired pattern.

Step 4: Then use the manual press to put the raw material of the sheet into the press. The back of the sheet can be made of acrylic plastic or metal. The specific material can be selected according to the customer's needs.

| Material | Tin | MOQ | 500PCS |

| Design | Customize | Sample time | 10 days |

| Colour | Printing | Production time | 30 days |

| Size | Customize | Packing | Customize |

| logo | Customize | Payment terms | T/T (telegraphic transfer) |

| Origin | China | Down payment deposit | 50% |

| Our advantage: | Years of professional experience; integrated service from design to production; rapid response; good product management; quick production and proofing. | ||

Products categories

-

Phone

-

E-mail

-

WeChat

Judy

-

Skype

Skype

-

Line

Line

-

Top

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur